Warehouse Flooring

Commercial Flooring for Warehouses & Storage

High tech resinous flooring, poured flooring, seamless flooring for warehouse & storage flooring applications.

Start Your Project

pride since 1993.

Commercial Storage & Warehouse Flooring

Client Applications

Warehouse epoxy coatings are a popular choice for flooring due to their durability, chemical resistance, and aesthetic appeal. Types of commercial warehouse flooring include:

Commercial Warehouse Flooring Benefits

Epoxy flooring is a good choice for warehouses and industrial/manufacturing spaces because it’s durable, easy to maintain, and improves safety.

Benefits of Epoxy Flooring for Warehouses

- Epoxy flooring can withstand heavy foot traffic, spills, and impacts.

- It can last for years and decades without showing damage.

- Epoxy flooring is resistant to abrasion and shock.

- Easy maintenance/cleaning

- Epoxy flooring is easy to clean with a mop, vacuum, or sweep.

- It’s resistant to stains and spills.

- Epoxy flooring is smooth and impenetrable, making it easy to clean.

- Safety

- Epoxy flooring’s glossy finish improves visibility, especially in dimly lit areas.

- It can be made anti-slip by adding sand, gravel, polymer grit, aluminum oxide, or mortar.

Other Benefits

Chemical resistance

Epoxy flooring is resistant to a wide range of chemicals and acids found in warehouse settings.

Environmentally friendly

Epoxy flooring is made from materials that are free from harmful substances.

Longevity

Epoxy flooring is a cost-effective option because it doesn’t need to be replaced as often.

Floor aesthetics

Epoxy flooring can protect the concrete floor beneath it from moisture, stains, grease, and cracks.

Durable

Epoxy flooring is designed to withstand heavy foot and vehicle traffic.

Easy to clean

The smooth surface of epoxy flooring is resistant to stains and spills, making it easy to clean with soap and water or a mop.

Slip resistant

Many epoxy flooring solutions have slip-resistant properties to improve safety in wet or oily conditions.

Seamless

The continuous, seamless surface of epoxy flooring leaves no cracks or crevices for bacteria, grime, and debris to build up.

Breathable

Some epoxy flooring systems, like Vent-E, allow moisture to pass through the concrete slab and coating. This helps prevent blisters and adhesion failures.

Sustainable

Some epoxy flooring systems are water-based and have low VOCs.

What flooring is used in a warehouse?

Light traffic Warehouses typically use a “grind and seal” which includes diamond grinding the floor with a heavy grinder and applying one coat of 100% solids clear epoxy, and one urethane layer for abrasion resistance. Medium use warehouses would be better served with a thicker more resistant product that is a three layer coating system. First a Primer, a 100% solids epoxy mid coat and a urethane layer for abrasion resistance. For a warehouse with heavy use, that would require a ¼ inch cementitious urethane mortar broadcast system with several topcoats.

What kind of flooring is ideal for a warehouse?

Different warehouses require different systems. Depending on the planned use of the space, the amount of traffic and type, forktruck, automated guided vehicles, cart traffic, etc. we can specify a system that fits your needs.

What is the best floor finish for a warehouse?

True mechanical Polishing is a great option, high gloss epoxy coatings are another. Matte, or satin, finishes are used as well. Really is a personal preference as to the appearance of the finished project. One exception, methyl methacrylate (MMA) flooring only comes in a matte finish.

What is the best flooring for industrial storage?

Cementitious urethane is the best option for heavy industrial coatings. This is tolerant of heavy traffic and heavy point loads, a lot of weight in one area.

What is the downside of epoxy flooring?

None. There is no downside to installing epoxy flooring in a warehouse. It brightens a building, makes it fresh and it’s easy to clean. Warehouse epoxy flooring shows your employees and customers that you care about your space. Makes your concrete impervious to chemicals and contaminants that can otherwise penetrate, therefore causing many issues i including deterioration and environmental concerns.

How much does warehouse flooring cost?

Costs can range from $3 per square foot to $25 per square foot and beyond. The cost depends on the floor preparation required, the quantity that needs to be completed, and the thickness and composition of the coating required. In other words, there are many variables that go into pricing.

Setup Your Flooring Consult Today

Contact Us to setup your commercial warehouse flooring consultation

Overview

and key features

Nuflorz can meet the demands of your Warehouse Flooring including dust-proof requirements, decorative, color-delineated, non-slip, chemical resistant, and more:

-

Dust Proof Flooring

-

Decorative Flooring

-

Non-slip Flooring

-

Seamless

-

Chemical Resistant Flooring

-

Static Dissipative Flooring

-

Food Storage Flooring

-

Cooler / Freezer Flooring

-

Impact Resistant Flooring

-

Color Delineation / Traffic Markings

-

Line Striping

-

Floor Labeling/Markings

-

Impervious to Production Fluids

-

Prevents Deterioration

-

Cleanable / Washable Surface

-

Workplace Environment & Worker Satisfaction

-

Safety Upgrades or Inspection Upgrades

-

Healthcare FDA / DEA Inspection Upgrades

Floor Coatings

We specialize in providing premium, high-performance poured flooring solutions designed to meet the specific needs of a wide range of industries.

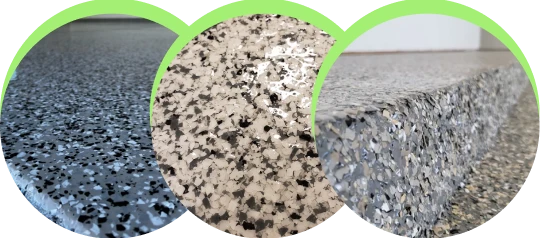

Epoxy Flooring

Epoxy flooring is a durable, seamless, and highly resilient surface solution, ideal for both industrial and commercial settings, offering superior resistance to wear, chemicals, and moisture while enhancing the aesthetic appeal of any space. Types of Epoxy include: Terrazzo Epoxy, Solid, Flaked, Metallic, Polished, and more.

Epoxy Flooring

Urethane Mortar / Cementitious Urethane Flooring

Urethane mortar, also known as cementitious urethane, is an exceptionally durable and chemical-resistant flooring solution, perfect for environments that experience extreme temperatures, heavy traffic, and frequent exposure to moisture, making it ideal for industries such as food processing and manufacturing.

Urethane Mortar, Cementitious Urethane Flooring

Polyaspartic Flooring

Polyaspartic flooring is a fast-curing, highly durable, and UV-resistant coating system, offering excellent protection against abrasion, chemicals, and impact, making it ideal for both indoor and outdoor applications where quick turnaround and long-lasting performance are essential.

Polyaspartic Flooring

Methyl Methacrylate MMA Flooring

Methyl Methacrylate (MMA) flooring is a fast-curing, highly durable solution that provides excellent chemical resistance and is ideal for environments requiring minimal downtime, such as commercial kitchens, hospitals, and industrial facilities, where flooring needs to be quickly installed and returned to service.

Methyl Methacrylate (MMA) Flooring

Polyurethane Flooring

Polyurethane flooring is a versatile and flexible surface solution known for its superior resistance to abrasion, impact, and chemicals, making it ideal for environments that require durability and elasticity, such as manufacturing plants, warehouses, and commercial spaces.

Polyurethane Flooring

Custom Flooring Projects

If you have a requirement for a coating / type not listed above, contact us.

Custom Flooring ProjectsThe Nuflorz Difference

We stand behind our floors so you can

on them

-

30+ Years in Business

-

Commercial & Industrial

-

Family Owned

-

Professional Grade

-

Stain, Wear & Impact Resistant

-

Unmatched Craftsmanship

-

Certified Floor Techs

-

Incredible Quality

-

Slip Resistant

-

Easy to Clean

Nuflorz High Performance Flooring System

Every project features a fully customized Nuflorz Flooring System, tailored to meet the unique needs of each client’s specific industry, application, usage demands, and detailed requirements.

Finish Layer

(3-5 mils, Clear, pigmented)- Provides a UV-stable wear layer

Grout/Top Layer

(10 – 12 mils) – Fills voids, provide uniform finish, strengthens

Base Layer

(1/16” – ¼”, Clear / pigmented / decorative). Can be used with, or to replace primer layer, depending on the system chosen.

Primer

(8-16 mils) – seals substrate to receive floor system. Can be used with, or to replace base layer, depending on the system chosen.

Concrete Substrate

pride since 1993.

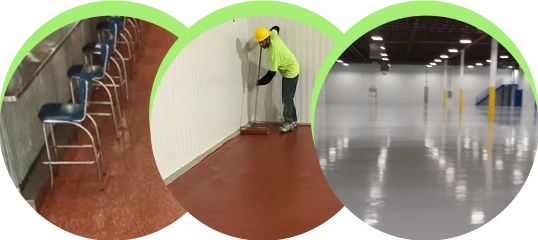

OUR PROCESS

-

Design, Planning & Estimating

Let’s talk about the various different problems that your industry may have, and how we will help you navigate, design & pick the right flooring system for your project. Some specific flooring requirements may include: Conductive Resin (ESD, static dissipative), Non-slip, Self leveling, vapor mitigation coatings, High performance, Decorative, seamless, chemical resistant, ergonomic, traffic coatings, safety flooring, antimicrobial, and more.

-

Installation

Well planned, organized installs from start to finish. Certified Installers, Long Term Employee Floor Technicians, Owner is always available.

-

Completion

Working together, we will meet your deadline.

-

Follow up

We will stay in touch, and ensure that you are educated on proper commercial epoxy floor care and maintenance.