Food & Beverage Flooring

Epoxy Flooring for Food & Beverage Production

Resinous flooring, poured flooring, seamless flooring for food and beverage manufacturing, farms, restaurants, kitchens, grocery, food service and more.

Start Your Project

pride since 1993.

Epoxy Flooring for Food & Beverage Production

Client Applications

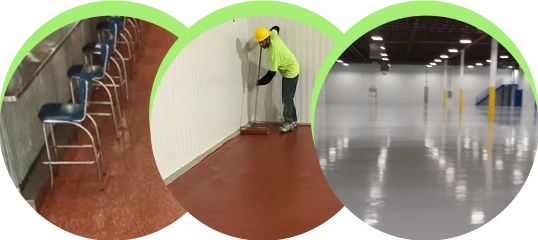

Epoxy coatings are a popular choice for food and beverage flooring due to their durability, safety, functionality, and compliance with industry standards. Types of food and beverage flooring include:

Food Production & Service Flooring

Beverage Production Flooring

Grocery Store Flooring

Restaurant Flooring

Farming Flooring

Kitchen Floors

Square Feet and Counting

Overview

and key features

Thermal shock resistant flooring is ideal for kitchen and food production facilities with fluctuating temperatures. During the food manufacturing process, it is common to empty and dump hot liquids onto the floor to drain. Our flooring resists these everyday thermal shock and oven temperature, is easy to clean, durable and can be non-slip.

-

Non-Slip Flooring

-

Foodsafe Flooring

-

Prevent Deterioration of the Floors

-

Improve the Workplace Environment – Aiding in Recruitment, Worker Satisfaction, Improved Production, and More

-

Cleanable / Washable Surface

-

Impervious Floor to Food / Beverages / Grease

-

Safety Upgrades or Inspection Upgrades

-

Healthcare FDA / DEA Inspection

-

Tour Ready

Floor Coatings

We specialize in providing premium, high-performance poured flooring solutions designed to meet the specific needs of a wide range of industries.

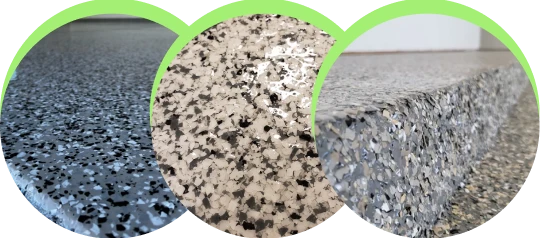

Epoxy Flooring

Epoxy flooring is a durable, seamless, and highly resilient surface solution, ideal for both industrial and commercial settings, offering superior resistance to wear, chemicals, and moisture while enhancing the aesthetic appeal of any space. Types of Epoxy include: Terrazzo Epoxy, Solid, Flaked, Metallic, Polished, and more.

Epoxy Flooring

Urethane Mortar / Cementitious Urethane Flooring

Urethane mortar, also known as cementitious urethane, is an exceptionally durable and chemical-resistant flooring solution, perfect for environments that experience extreme temperatures, heavy traffic, and frequent exposure to moisture, making it ideal for industries such as food processing and manufacturing.

Urethane Mortar, Cementitious Urethane Flooring

Polyaspartic Flooring

Polyaspartic flooring is a fast-curing, highly durable, and UV-resistant coating system, offering excellent protection against abrasion, chemicals, and impact, making it ideal for both indoor and outdoor applications where quick turnaround and long-lasting performance are essential.

Polyaspartic Flooring

Methyl Methacrylate MMA Flooring

Methyl Methacrylate (MMA) flooring is a fast-curing, highly durable solution that provides excellent chemical resistance and is ideal for environments requiring minimal downtime, such as commercial kitchens, hospitals, and industrial facilities, where flooring needs to be quickly installed and returned to service.

Methyl Methacrylate (MMA) Flooring

Polyurethane Flooring

Polyurethane flooring is a versatile and flexible surface solution known for its superior resistance to abrasion, impact, and chemicals, making it ideal for environments that require durability and elasticity, such as manufacturing plants, warehouses, and commercial spaces.

Polyurethane Flooring

Custom Flooring Projects

If you have a requirement for a coating / type not listed above, contact us.

Custom Flooring ProjectsThe Nuflorz Difference

We stand behind our floors so you can

on them

-

30+ Years in Business

-

Commercial & Industrial

-

Family Owned

-

Professional Grade

-

Stain, Wear & Impact Resistant

-

Unmatched Craftsmanship

-

Certified Floor Techs

-

Incredible Quality

-

Slip Resistant

-

Easy to Clean

Nuflorz High Performance Flooring System

Every project features a fully customized Nuflorz Flooring System, tailored to meet the unique needs of each client’s specific industry, application, usage demands, and detailed requirements.

Finish Layer

(3-5 mils, Clear, pigmented)- Provides a UV-stable wear layer

Grout/Top Layer

(10 – 12 mils) – Fills voids, provide uniform finish, strengthens

Base Layer

(1/16” – ¼”, Clear / pigmented / decorative). Can be used with, or to replace primer layer, depending on the system chosen.

Primer

(8-16 mils) – seals substrate to receive floor system. Can be used with, or to replace base layer, depending on the system chosen.

Concrete Substrate

pride since 1993.

OUR PROCESS

-

Design, Planning & Estimating

Let’s talk about the various different problems that your industry may have, and how we will help you navigate, design & pick the right flooring system for your project. Some specific flooring requirements may include: Conductive Resin (ESD, static dissipative), Non-slip, Self leveling, vapor mitigation coatings, High performance, Decorative, seamless, chemical resistant, ergonomic, traffic coatings, safety flooring, antimicrobial, and more.

-

Installation

Well planned, organized installs from start to finish. Certified Installers, Long Term Employee Floor Technicians, Owner is always available.

-

Completion

Working together, we will meet your deadline.

-

Follow up

We will stay in touch, and ensure that you are educated on proper commercial epoxy floor care and maintenance.